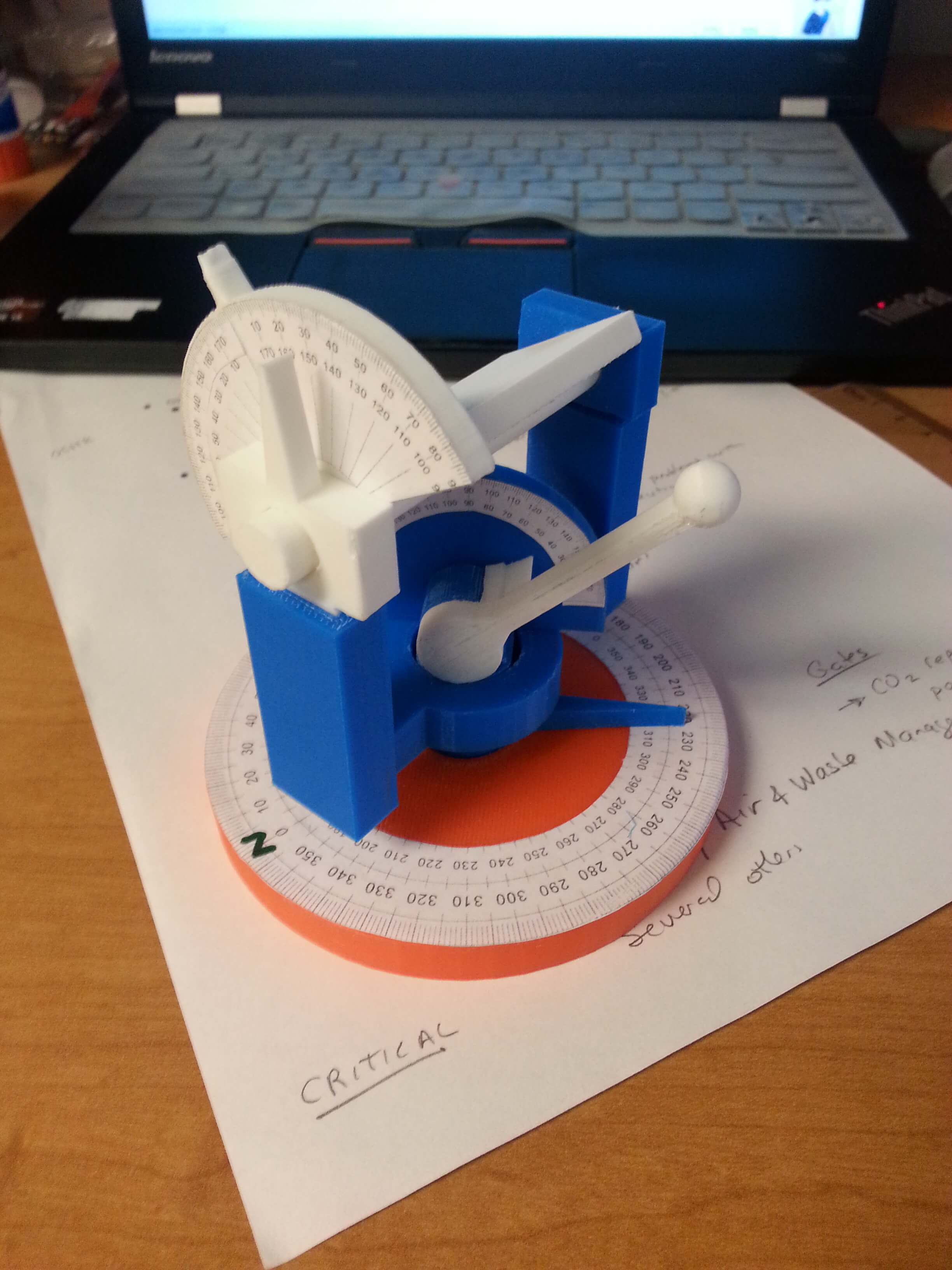

Meet the Maker : Austin Keating

/Sometimes you can settle for a $20 lamp from Target, but other times, you want something more. Recently, an amateur Maker came to the Makerlab to look at his options.Austin Keating, a Junior at the University of Illinois, came to the lab in September and found what he was looking for on thingiverse: A Jigsaw Puzzle Lamp. As a Journalism major without any experience in modeling, Austin said he found the undertaking was easy, with the help of Makerlab staff. He said he looks forwarding to making more, and views his experience as an entry point into building his own designs. Based on his experience he also signed up for the "Digital Making" course for Spring 2015

http://youtu.be/vhWaXygF3eI

Meet our other makers . Stay tuned for updates by subscribing to our blog feed, or just get our posts via email. You can also like us on Facebook or follow us on twitter to stay updated. Have an interesting story about making at the lab? Just drop us a note at UIMakerLab@illinois.edu.